No compromise in product quality

-

High-quality ingredients

-

In-house analytical laboratory

-

Continuous product development

-

Facilities are HACCP, GMP and HALAL certified

-

Quality management certificates

Quality management certificates

- 230 000+ quality tests annually

- 100 % safe and doping-free products

- 2000+ product variations

Quality begins with the best ingredients

The quality of our ingredients defines the character, nutritional value, special properties, and overall enjoyment of our products, ultimately leading to customer satisfaction. Therefore, during the product development and procurement processes, we pay exceptional attention to the careful selection of these ingredients. Our products are exclusively made using high-quality, carefully sourced, and safe ingredients. Every batch of incoming and production materials undergoes rigorous qualification and evaluation based on a strict rating system. Only ingredients that strictly meet our quality standards and adhere to specified limits are eligible for use in the production process.. If an ingredient doesn’t meet our criteria, it is rejected and returned. To ensure the safe and consistent quality delivery of our products, we place special emphasis on our choice of packaging materials. Our product packaging is always designed based on the specific characteristics of each product, and the packaging process undergoes thorough internal scrutiny to ensure that our customers always receive products of impeccable quality.

All BioTechUSA facilities are HACCP, GMP and HALAL certified.

-

Safe ingredients

-

Reliable quality

Security assessments and protocols

We have multiple laboratories, allowing us to conduct in-house testing for various parameters and product attributes related to our ingredients. Our own results are regularly confirmed with measurement results from external accredited laboratories. Our factories meet the strictest food safety standards, both in terms of their technological design and their operation. But our goal is not only to meet but to exceed the expectations of these standards in our facilities. We continuously improve our quality and efficiency. Hygiene is a top priority for our manufacturing facilities and production lines. We also pay extra attention to the personal hygiene of our employees. We use safe cleaning agents designed for food industry and purified water for cleaning our production lines. Our factories are operating at controlled temperature and humidity levels, with a special filtration system that ensures the supply of clean air for safe food production.

-

Innovative product development

-

In-house analytical laboratory

-

Safe environment

Professional Technological Processes

To guarantee consistent high quality, in addition to using the right ingredients, we employ strict technological processes and precise recipes in the production of our products. This means that ingredients are added to the product in specified quantities, and this measuring process is controlled by a professional software. In practice, this solution allows us to ensure that our products are always made according to the recipe, with no deviations between production runs. Thanks to this, every step of the product manufacturing process is traceable through our company management system and security systems, from the first step to the last, when it goes to our stores or partners.

-

Proprietary recipes

-

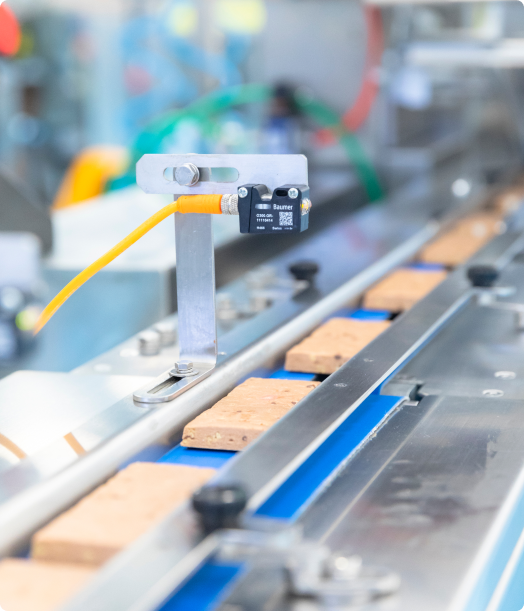

Automated manufacturing processes

Constant Quality Control

Following the measurement, the next step in our manufacturing process is the creation of the powder mixture. Each ingredient is delivered to the mixing container in a predetermined order through a control sieve. After an individually specified mixing time for each product, the mixture is discharged into filling containers. The mixing machines are carefully isolated from each other and located in separate rooms to prevent cross-contamination. Every mixing batch goes under a sensory inspection conducted by trained experts for each production batch. The mixed product is compared to a reference standard to ensure that our product consistently meets the desired texture, taste, and colour. Following these sensory inspections, the products move on to the next phase of production, which is packaging. In addition to powdered products, our manufacturing facilities also produce capsules, tablets, and sliced products. These products involve multiple steps in the manufacturing process, and the finished products undergo additional checks before entering the packaging area.

-

Sensory inspections

-

Random product analyses

The customer comes first

We conduct over 230,000 product quality inspections annually, averaging nearly 1,000 inspections per day, to ensure that our products meet the strictest internal standards, food safety regulations, and quality guidelines. Our primary goal is continuous improvement and achieving the highest possible level of quality, thereby ensuring a positive consumer experience. To achieve this, we regularly hold internal and external training sessions to further develop our quality and food safety culture. We actively invest in the development of our factories, equipment, and machinery to guarantee the long-term production of safe and high-quality products, regardless of the brand.

-

Qualified professionals

-

230.000+ quality inspections

-

Customer-centric mindset